Manufacturers of original and heavy engineering equipment struggle with the high pace production because of paint curing times. They can usually produce parts faster than they can paint and dry them due to bottle-neck’s caused by traditional paint curing times.

Traditional coatings require atmospheric conditions to be perfect and controlled, and usually require paint booths and electrical dryers to accelerate the paint cure. Even then parts are sometimes left to cure for a week if the assembly process involves bolts and screws which would otherwise shear the paint. With MCU-Coatings even a three-coat paint system on a SA 3 prepared surfaces can be applied within 2 hours!

One of our OEM clients had issues with his old coatings because they were shearing underneath the bolts and washers 7 days after the coatings had been applied because they still had not dried hard. He changed to MCU-Coatings because he was able to assemble parts 2 days after they had been coated.

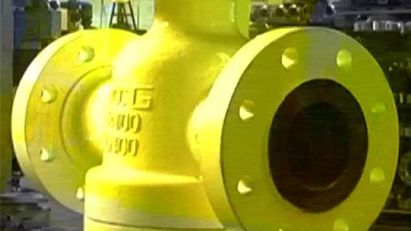

Our standard paint system for hard wearing equipment: 100µm DFT MCU-Zinc primer, 125µm DFT MCU-Miomastic followed by 75µm DFT Topcoat – total DFT of 300µm:

Other relevant features:

MCU-Coatings guarantees faster application times and greater efficiencies which translate into profits!

Fill out the form below. We are interested in new projects, big or small